Electronic Hammer Technology

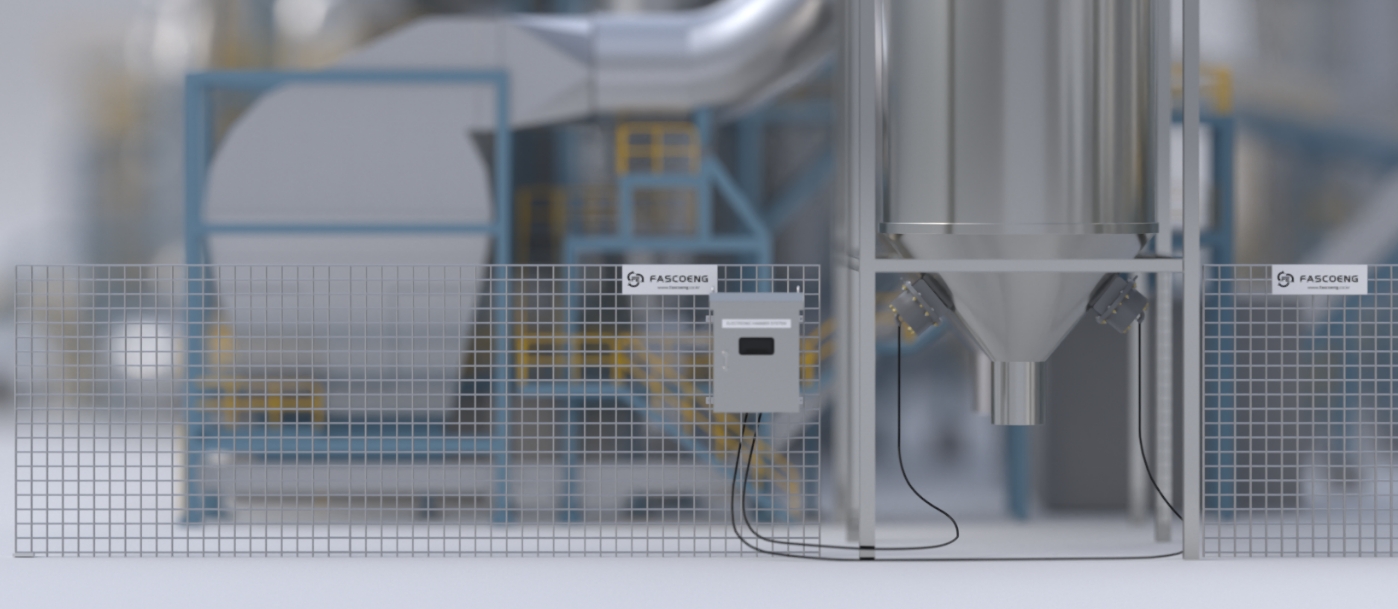

The driver that operates the electronic hammer is typically installed inside the electrical panel. It creates and transmits electrical signals for more effective operation of the electronic hammer and operates the electronic hammer with various safety devices.

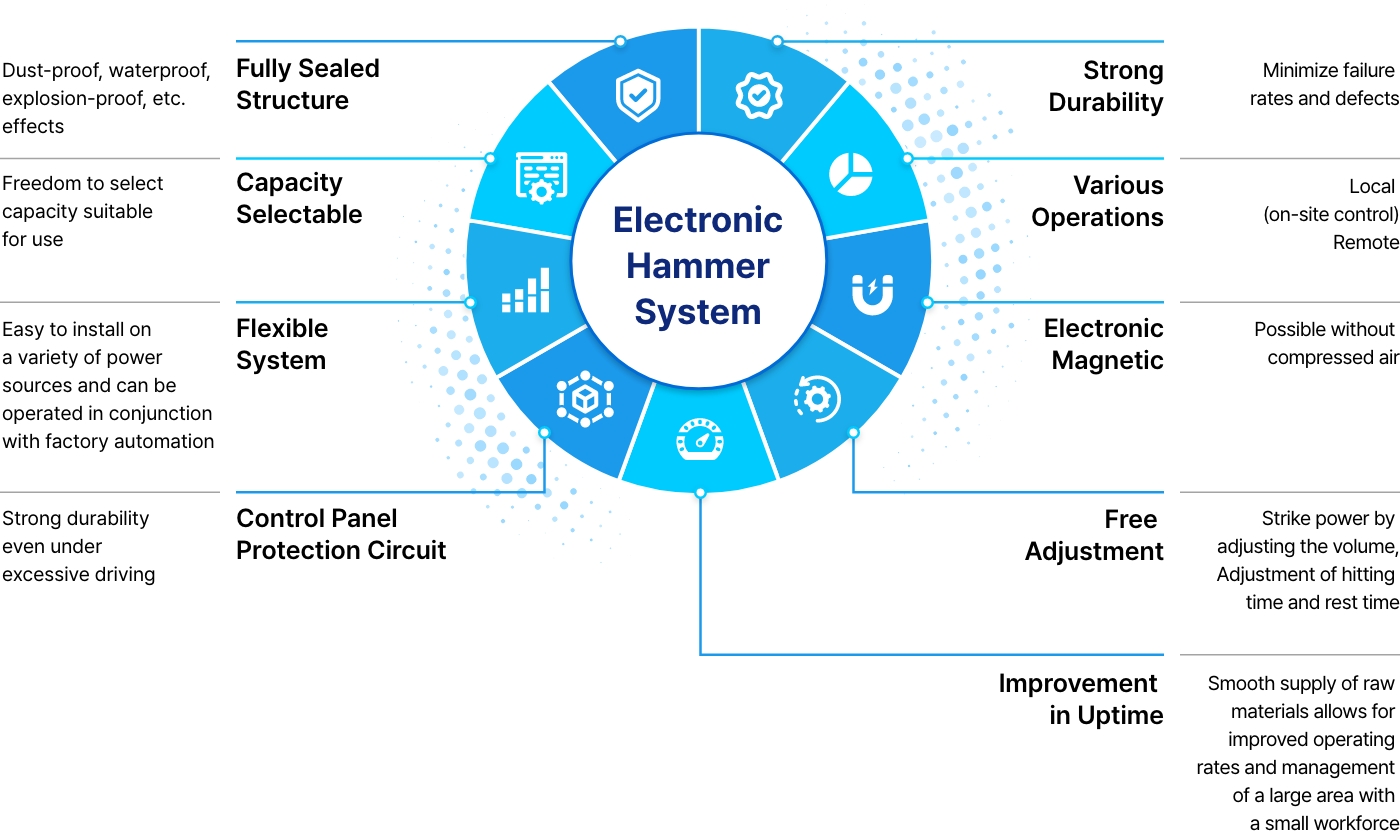

Electronic Hammer System Technology

Function

- On-site control and remote control operation

- Multiple electronic hammers controlled

by a single controller

Controller

Controller

Electronic Hammer Excellence

Electronic Hammer Solutions

Electronic Hammer Features

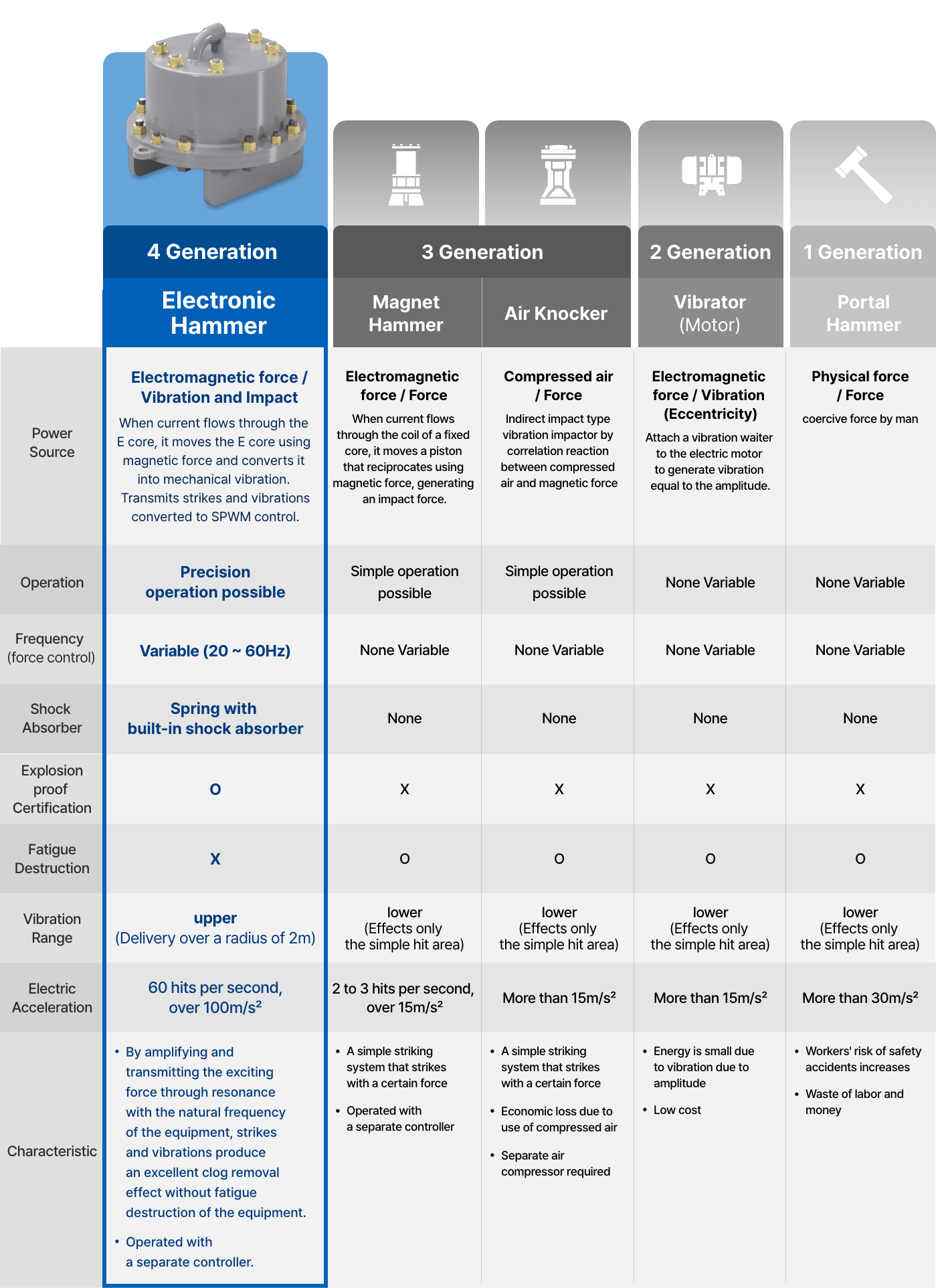

System Principles

-

Electromagnetic Force Generation

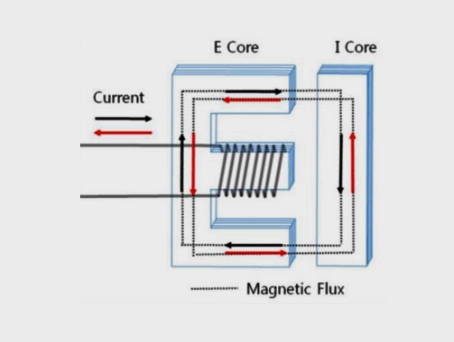

Electromagnetic Force GenerationWhen alternating current flows through the wire wound around the E-core, electromagnetic force is generated between the E-Core and I-Core by electromagnetic principles

-

Mechanical Vibration Generation

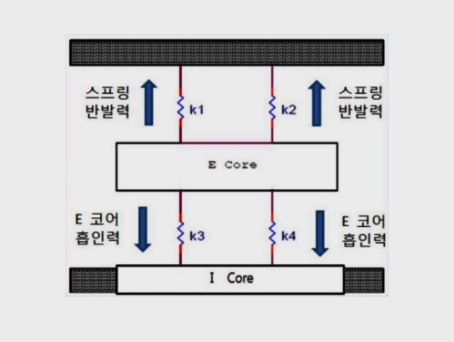

Mechanical Vibration GenerationMechanical vibration and impact occur through the restoring force of elastic springs against electromagnetic force

-

Vibration Radius

Vibration RadiusDelivers and amplifies momentary powerful impact and vibration to equipment surfaces, transmitting force to inner walls to prevent powder deposits and caking

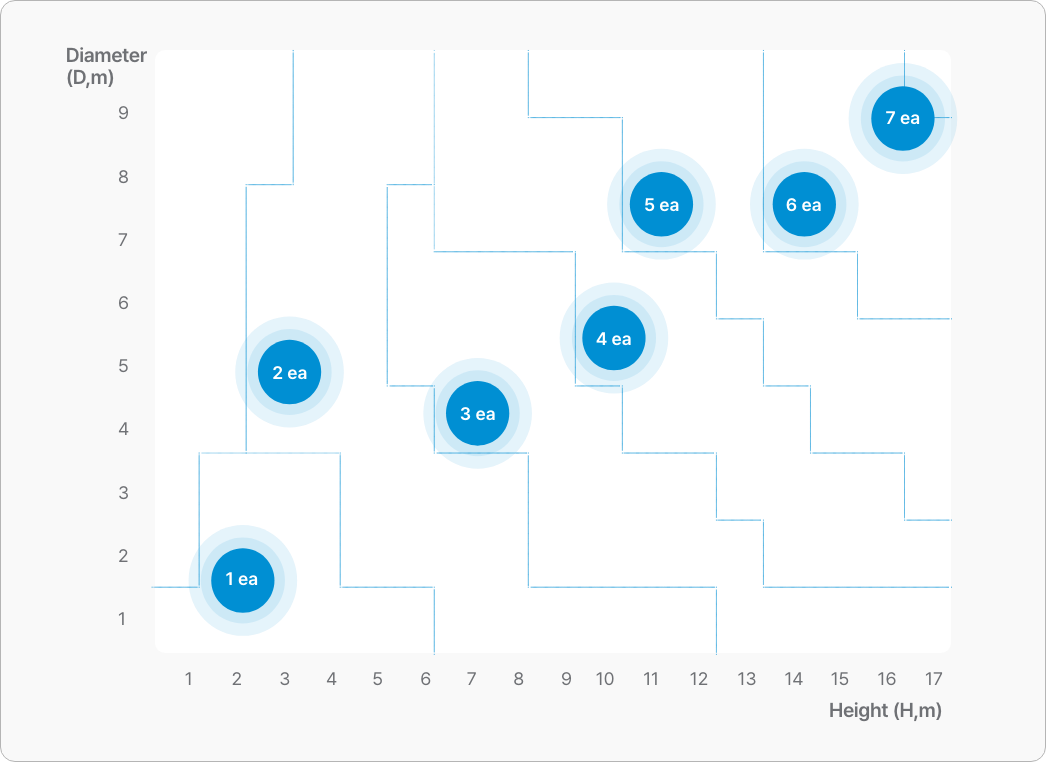

Specification Selection Criteria

Equipment Proportional Conditions

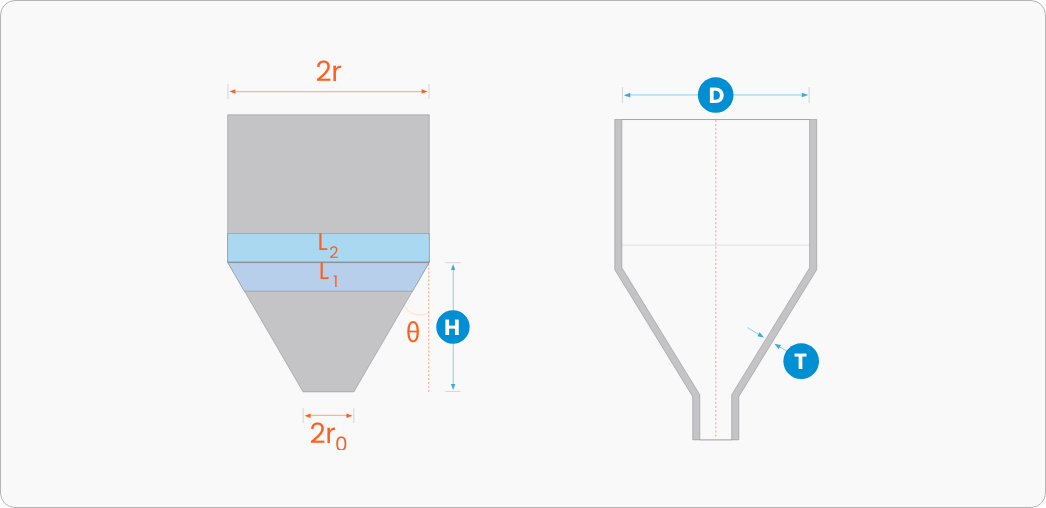

Models and quantities are selected based on diameter (D) and hopper plate thickness (T), with a hopper angle of repose of 60°. However, these may vary depending on hopper shape, powder properties, and conditions.

Installation

Quantity

Conditions

The chart below is based on 10mm thickness (T) and does not consider 2ro and L1, L2.

The number of hammer installations may vary depending on circumstances.